|

|

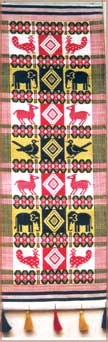

Wall hanging |

by ASIFF HUSSEIN

Sunday Observer Apr 27 2003

There was a time when the famous Dumbara mats were much talked about and sought after by the cultured circles of Sri Lankan society not very long ago.This however no longer appears to be the case today at a time when the love for things old is gradually declining, but hopefully not for long.

There is an increasing trend worldwide to go back to nature and culture and it can only be hoped that this catches on here as well. Such a development will no doubt bode well for our indigenous crafts such as the weaving of Dumbara mats which is unique to Sri Lanka.

Solitary village

Dumbara mats, also known as kalala or Dumbara rata paduru are today produced in a solitary village known as Henavala in the Pata Dumbara division of Kandy district. The traditional mat-weaver caste known as the Kinnaras who inhabit this village still employ an age-old weaving process to produce the mats from the fibre of the hana or sann hemp (Crotalaria juncea).

|

|

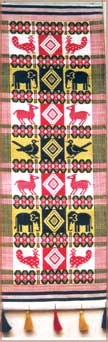

Wall hanging |

Although Ananda Coomaraswamy observed in his Medieaval Sinhalese Art published in 1908 that the Dumbara mats were made from the niyanda or bowstring hemp (Sansevieria zeylanica) this no longer appears the case, as we found out in our visit to Henavala early this month. The reasons attributed to the decline of niyanda by the villagers was the scarcity of the plant and insufficient fibre for large-scale manufacture.

Indeed, it appears that the shift from niyanda to hana was beginning to take place about a century ago a short while after Coomaraswamy published his monumental work. For instance, an expert weaver Harispattuvagedara Sirivardana told us that he had heard that niyanda was used in his father's time and that it was used until about a hundred years ago. Sirivardana who learnt the trade from his father Harispattuvagedara Punchina does not usually employ the hana plants growing in the vicinity as it is not sufficient for his purpose but instead purchases it from others who obtain the leaves some 30-40 miles away.

The leaves are then scraped against a log with a sharp implement and this removes the fleshy part of the leaf leaving behind the fibre. The fibre is then dyed with natural dyes obtained from plants such as patangi (Caesalpinia sappan) which yields a red dye, venivel (Coscinium fenestratum) which gives a yellow dye, katarolu (Clitorea terneata) which gives a purplish dye and bulu (Terminalia belerica) which yields a black dye when combined with certain chemical agents known as mordents.

|

|

Some of Sirivardana’s products |

These dyes were introduced by the National Design Centre in Nattarampota, Kandy and has found favour with Sirivardana though it has yet to catch on with some of the other villagers.

The loom used to weave the final product somewhat resembles the old looms used in cotton weaving, though it is a much more simple contrivance. The weaving itself appears to be a time-consuming process and needs a lot of skill and patience.

Nevertheless the final product is worth it and fetches a fair price. The Dumbara mats or rata paduru produced here are however strictly speaking not mats in the conventional sense meaning that they are not meant for sitting upon, but rather in the form of wall hangings (bitthi sarasili).

These wall hangings come in a variety of colours and designs with motifs of flowers and various fauna such as deer, elephants, cobras and peacocks figuring prominently in them. Besides wall hangings, Sirivardana turns out various other products from hana fibre such as colourful women's handbags and letter holders of various shapes and sizes.

Unforgettable sight

Pansalvattegedara Manika, a native of Henavala who claims to have been weaving mats for the past 40 years however has his woes as well. Manika who obtains his own fibre said that although he encounters no problem in removing hana leaves from forest or crown lands, problems arise when he attempts to do so in private lands. Private land owners, he contends, oppose his harvesting of their plants as they feel he derives a good income from it which is however not at all the case.

|

|

Hana plant |

Manika manufactures wall hangings, hand bags, table mats, purses and pencil cases from hana fibre which he supplies to outlets such as Laksala, Lakpahana and the Udarata Kala Sangamaya.

Kotavattegedara Jayasena, yet another native of the village works in a Laksala manufacturing centre in the village along with five others. The produce is supplied to Laksala and some private firms.

Here we beheld a truly unforgettable sight. Working on the looms side by side was a veritable greybeard his face wizened with age and a strapping lad in the bloom of youth. Here at least was a moment that seemed to transcend the age barrier and the much talked of generation gap.